Our Competitive Strength

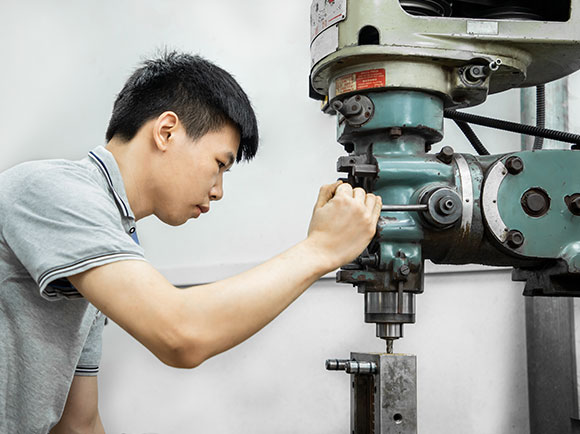

Efficient team, perfect production line and complete modern production equipment including milling machines, grinding machine, electrical discharge machines, and injection molding machines, can provide you the needed auto parts and services in the first time.

Our in-house manufacturing process of rare classic parts includes mold tool design, custom fabrication and full inspections of finished parts. The core of quality control and strong manufacturing capability enables us to be more competitive, which includes superb mold-design, precise chrome plating and exquisite technological process in all parts fabricated.

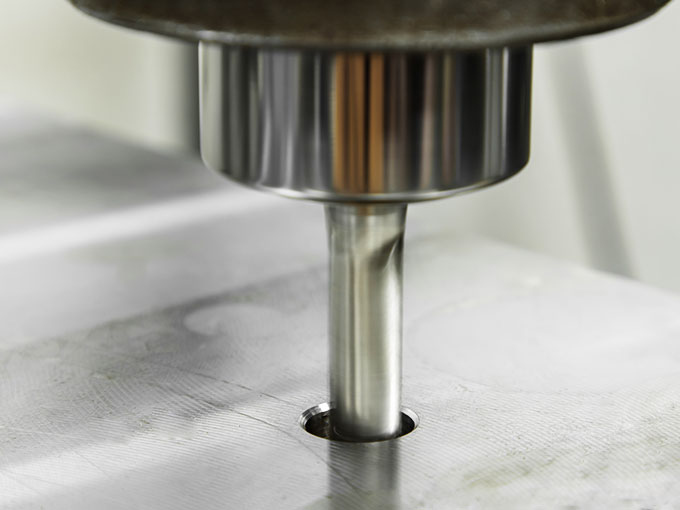

Superb Mold-design

As an outstanding manufacturer in producing high-quality plastic injection molded parts and mold tools, our success is to deliver excellent products in the shortest possible time and at the lowest possible cost.

We pioneered the manufacture of extruded die steel, and continue to attain new standards of OE quality. We guarantee obvious precision and reliability.

How We Process

Precise Chrome Plating

Using chrome plating technology is more reflective, bluer, and specular than other finishes.

it is a long involved process that often starts with tedious polishing and buffing, then cleaning and acid dipping, zincating (if the part is aluminum), and copper plating. The technology of vacuum metalizing & metallic coatings is extremely remarkable in our production.

A chrome surface also resists corrosion, making it suitable for use in harsh environments or where other plating materials would wear away, exposing the substrate metal to corrosion attack.

Exquisite Technological Process

A complete series of production for a part is not an easy task, so it’s necessary to work together closely with different manufacturers. Sunway has cooperated with well-reputated manufacturers for many years, and we will do our best to reach parts quality equal to the original standard, from pressing, soldering, spraying, to assembling and delivering. And we have professional warehouse management for stock.