The V8 engine is not merely a cylinder design; it is the pulse of industrial aspiration and the ultimate theme song to the golden era of motoring. The V8, two banks of four cylinders mounted in a 90-degree V, has been the mass-market dominant power unit in the world since its introduction into the mass market in the early 1900s. It combined the shortness of a four-cylinder with the uninterrupted, inexorable thrust of eight, to provide a firing rate of every 90 degrees, which in a straight engine was by no means comparable. By the year 2026, when electric torque will be silent and silent electric power is more the tool than the tonic, the visceral bellowing of a V8 and its mechanical soul has become a heritage, to be treasured.

However, what makes the best V8 engine? Is it the unseated and unrefined horsepower of a modern supercar or the invulnerability of a mid-century workhorse? To the enthusiast, the restorer, and the collector, the best is a three-fold combination of performance, historic interest, and metallurgical serviceability. In this ultimate reference, we learn about those engines that did not simply push cars–they pushed the world.

What Makes a V8 “Built to Last”?

The development of longevity in an internal combustion engine is not a coincidence; it is a planned engineering decision, as it was in a time when over-engineering was the new normal. To grasp the answer to the question of what makes a V8 live, one has to go beyond the spec sheet and to consider the material science.

1. Thermal Management and Block Integrity

Heat is the major adversary of any engine. V8s, which remain half a century old, may include high-nickel cast iron blocks. This material has better dimensional stability than early aluminum alloys, able to withstand the warping that causes the failure of head gaskets. Moreover, engines that have been developed at low stress, i.e., giving high torque at lower RPMs, have much less internal wear than high-strung, high-revving engines.

2. The Architecture of Balance: Cross-Plane vs. Flat-Plane

Harmonic balance also produces mechanical longevity. The common type in the US muscle and luxury cruisers is the Cross-plane V8, with heavy counterweights on the crankshaft, to counter primary and secondary vibrations. This smoothness in nature decreases the wear on the main bearings and engine mounts in hundreds of thousands of miles.

3. Lubrication and Filtration

Virtually all engines that are members of the “million-mile” club have high-volume oil pumps and advanced gallery designs. In the 2020s, we have had the experience that classic engines may actually outlive their design capacity with modern synthetic lubricating oils and high-efficiency filtration systems that can filter out micron-level particulates that could not be effectively filtered out by the filters of the 1950s.

| Feature | Cast Iron Era (1930s-1970s) | Modern Alloy Era (1990s-2026) |

| Primary Material | High-Nickel Grey Iron | Silicon-Aluminum (Alusil/Nikasil) |

| Typical Lifespan | 150k – 300k Miles (before rebuild) | 200k – 400k Miles (with precision maintenance) |

| Maintenance Profile | Simple, frequent (Gaskets/Carbs) | Complex, infrequent (Sensors/Timing Guides) |

| Restoration Potential | Extremely High (Heavy casting allows boring) | Moderate (Requires sleeves or specialized coating) |

The Top 10 Best V8 Engines of All Time

To compile a definitive Top 10 in 2026, we have to go beyond the production figures. These entries were chosen due to their radical changes in automotive architecture, due to the dominance of their respective racing series, or due to the degree of reliability that contravened the planned obsolescence of their times. That is the big blocks that made the V8 worthy of the title of the best powertrain.

1. Ford Flathead (1932-1953)

V8 engines were relatively expensive, multi-Casting, and only the very wealthiest could afford them before the Flathead. The masterstroke of Henry Ford was the so-called En Bloc-construction, which is the casting of the whole cylinder block and crankcase of pure iron. This was a miracle in production in 1932. Architecturally, it followed a side-valve or L-head design, with the valves being in the block beside the pistons.

Although this restricted airflow to the modern overhead-valve design, this compact size and simplicity made it the DNA of the American Hot Rod. Real world, it was so popular with moonshine runners and early racers in the real world that its low-end torque made it both affordable and indestructible, demonstrating that V8 power could be affordable and invulnerable at the same time.

| Parameter | Specification |

| Crankshaft Type | 90° Cross-plane (Forged Steel) |

| Compression Ratio | 5.5:1 to 7.5:1 (Depending on year) |

| Valvetrain Layout | Side-valve (L-head), 16 Valves |

| Peak Horsepower | 65 hp – 125 hp (Factory stock) |

2. Small Block Chevrolet (SBC)

Introduced in 1955, the SBC (with a 4.3 litre or 265 cu in minimum capacity) made virtually all other contemporary engines obsolete. It was a lighter and more efficient block that could be achieved with its own distinctive casting technique that did not compromise strength. The design employed the use of a central camshaft and pushrods to open overhead valve- a design that was so efficient that even today, GM uses a refined version of the design. It is special because it is interchangeable; a component of a 1960s 350 can regularly be used in an engine produced decades afterwards. At the street, the SBC specified the sleeper, which was the lightweight engine that could be modified to deliver twice its factory performance through the use of basic bolt-on components.

| Parameter | Specification |

| Bore x Stroke | 4.00 in x 3.48 in (Typical 350ci) |

| Main Bearings | 2-bolt or 4-bolt (High-performance) |

| Induction | Carbureted / Mechanical Fuel Injection |

| Specific Power | ~0.8 to 1.1 hp / cu in |

3. Chrysler 426 HEMI

Elephant Engine was given its name by the physical size as well as the crushing capacity of the engine among Mopar fans. The characteristic is the hemispherical combustion chamber that enables huge, sloping valves and a centrally positioned spark plug. This design offers an almost direct route to the air-fuel mixture, and this gives unprecedented volumetric efficiency.

Originally built for NASCAR dominance, this Mopar myth was a visceral accelerator that characterized the V8 Muscle Car age, as hemispherical cylinder heads turned out to be the panacea of raw, naturally aspirated motive.

| Parameter | Specification |

| Block Material | Cast Iron (High-nickel alloy) |

| Head Design | Hemispherical Aluminum or Iron |

| Peak Torque | 490 lb-ft @ 4000 RPM |

| Cylinder Spacing | 4.80 in (Center-to-center) |

4. General Motors LS Series

Launched in 1997, the LS series proved that the “old-fashioned” pushrod (OHV) design could outperform high-tech overhead-cam engines. Its uniqueness comes from the 6-bolt main bearing caps and deep-skirt block design, which provides extreme structural rigidity.

The LS combines a small physical footprint with massive displacement potential. Its real-world effect is most visible in the “LS-Swap” subculture; because of its power-to-weight ratio and reliability, it is the universal engine of choice for everything from drift cars to classic truck restorations.

| Parameter | Specification |

| Block Type | Deep-skirt Aluminum or Cast Iron |

| Redline | 6,500 – 7,000 RPM (Stock) |

| Weight | ~460 lbs (Aluminum versions) |

| Fuel System | Sequential Multi-Port Fuel Injection |

5. Mercedes-AMG M156

M156 was something new to AMG-their first clean sheet engine that was completely in-house. It is a 6.2-liter DOHC constructed to be a large-displacement high-revving engine. It also has a special closed-deck crankcase and a special wire-arc sprayed coating (LDS) on the cylinder walls in order to minimise friction.

Out in the world, the M156 is known to have a hammer of Thor exhaust note and a linear power delivery incapable of being matched by turbocharged engines. It transformed executive sedans such as the C63 into tire-shredding monsters and retained German accuracy.

| Parameter | Specification |

| Displacement | 6,208 cc |

| Valvetrain | DOHC, 32-valve, Variable Valve Timing |

| Crankshaft Material | Forged Steel (Cross-plane) |

| Max Power Output | 451 hp – 518 hp (Varies by model) |

6. Ferrari F136

The F136 (Ferrari variants in particular) with the flat-plane crankshaft is the epitome of Italian passion. This architecture, as opposed to the “rumble” of an American V8, produces a high-pitched, F1-style scream. The flat-plane layout enables the firing order to be alternating between cylinder banks to optimize the exhaust scavenging. This engine delivered an astounding 125 hp per liter in the Ferrari 458 Italia – at the time a world record among naturally aspirated production engines. It is a motor that requires all the attention of the driver, and it pays him back with razor-throttle response.

| Parameter | Specification |

| Crankshaft Type | Flat-plane (180° offset) |

| Redline | 9,000 RPM |

| Lubrication | Dry Sump System |

| Specific Output | 125 hp / Liter |

7. BMW S65

The S65 is merely a 4.0-liter derivative of the iconic BMW S85 V10. It is a state-of-the-art masterpiece that has throttle bodies (ITB) with one throttle body per cylinder, which enables the throttle to open and close immediately. What makes it special is the fact that it has an ionic current knock detection system that employs the spark plugs to track the process of combustion.

Even though it is complicated, it is lighter than the six-cylinder engine it has taken the place of. It gives the E92 M3 a surgical-type driving experience where it screams to an 8,400 RPM redline with the accuracy of a racing instrument.

| Parameter | Specification |

| Engine Weight | 445 lbs (202 kg) |

| Compression Ratio | 12.0:1 |

| Cylinder Heads | One-piece Aluminum Casting |

| Engine Management | MSS60 (With 10 Individual Throttles) |

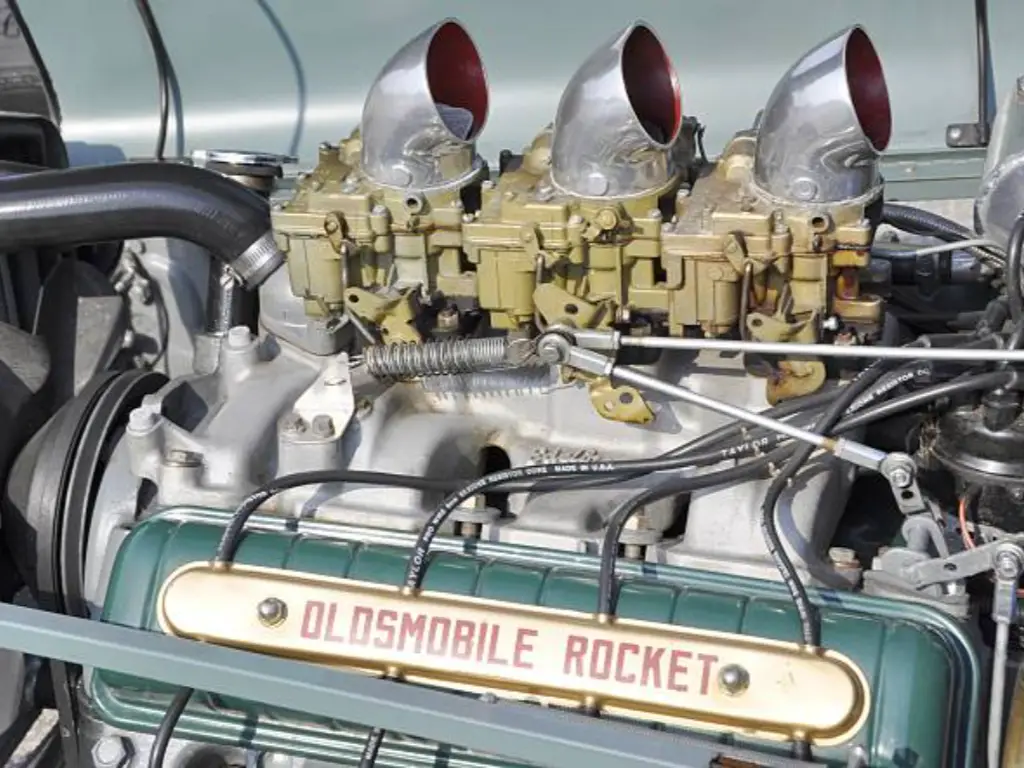

8. Oldsmobile Rocket V8

Although the V8 trend was initiated by the Flathead, the Oldsmobile Rocket V8 of 1949 marked the beginning of the Horsepower Race. It became the first mass-produced high-compression overhead-valve (OHV) V8. It was also designed with a short stroke that enabled it to rev higher and run better compared to long-stroke engines in the 1930s. Its practical impact was revolutionary; it turned Oldsmobile into the quickest automobile on the highway, which won the first NASCAR manufacturer’s championship, and it established the prototype of all American V8s to come over the following four decades.

| Parameter | Specification |

| Displacement | 303 cu in (Initial Launch) |

| Cylinder Bank Angle | 90 Degrees |

| Valvetrain | OHV, Hydraulic Lifters |

| Bore x Stroke | 3.75 in x 3.43 in |

9. Toyota 1UZ-FE

The 1UZ-FE is the “Best V8” for those who value engineering perfection over raw aggression. Developed with a near-infinite budget for the Lexus LS400, it features race-inspired architecture: 6-bolt main bearings (unheard of in luxury sedans at the time) and an aluminum block with extremely tight tolerances. Its uniqueness is its silence; at idle, it is virtually vibration-free. However, its actual strength is immortality. It is widely documented to exceed 500,000 miles with only basic maintenance, proving that a V8 can be both high-performance and a “lifetime” machine.

| Parameter | Specification |

| Internal Construction | Forged Steel Crank & Connecting Rods |

| Main Bearing Caps | 6-bolt (Cross-bolted) |

| Camshaft Drive | Belt-driven DOHC |

| Expected Lifespan | 300,000 – 1,000,000 Miles |

10. Ford Coyote 5.0

The Coyote represents the evolution of the Ford “Modular” family into a world-class powerhouse. Its signature feature is Twin Independent Variable Cam Timing (Ti-VCT), which allows the engine to adjust intake and exhaust timing on the fly for maximum efficiency or maximum power. The architecture is a high-revving DOHC design with high-flow four-valve heads. In the modern Mustang, the Coyote delivers the best of both worlds: a civilized, fuel-efficient commuter at low RPMs and a 480+ hp beast that pulls hard all the way to 7,500 RPM.

| Parameter | Specification |

| Valvetrain | DOHC with Ti-VCT (4 Valves per Cyl) |

| Firing Order | 1-5-4-8-6-3-7-2 |

| Piston Material | Hypereutectic Aluminum Alloy |

| Redline | 7,500 RPM (Gen 4) |

Restoration Realities: Overcoming the Challenges of Aging V8s

By 2026, possessing a classic V8 is going to be in the NOS drought. Original engine components from the 1920s-1990s have been greatly affected by dry rot or corrosion. Moreover, the current ethanol-containing fuels dissolve the cork and rubber gaskets that these old engines were initially constructed with, chemically. Nano-warping by decades of thermal cycles also means that original-spec components frequently are unable to fit properly against aged surfaces.

Three avenues are usually available to survive these legends: risky salvage hunting, costly hand machining, or aftermarket replacement in modern times. The latter is the most sustainable, as it gives an opportunity to incorporate 21st-century material science – such as fluoroelastomers – resistant to both heat and chemical destruction, much better than initial mid-century substances.

Such is the gap filled by Sunway Autoparts. This is where Sunway Autoparts bridges the gap. Since 2007, we have specialized in providing the “missing links” of automotive history—those elusive engine components, from precision pistons to intricate gaskets, that keep mid-1920s to late-1990s legends on the road. It is not the reproduction of parts that we engage in, but the bettering of them. We address the structural weakness of ageing components by using hi-tech, high-quality polymers and casting metal to OEM standardization and above. Our network of approximately 200 suppliers and understanding of various production industries allows us to offer the custom piston or dependable bulk gasket you require to make your V8 a car that would be built to last.

Buying Guide: How to Evaluate a Classic V8 in 2026

When you are shopping for an old-fashioned V8, it is all about higher stakes than ever. Being older than 40 years on average, originality is not necessarily a quality of these engines. The following is a special point of view as to what to seek:

1. The Fluid Analysis (The Blood Test)

Pull the dipstick before the car has even started. But not only look at the color, but also touch the grit. Portable oil analysis kits are commonly used by professional purchasers in 2026. High copper or lead traces indicate that the main bearings are near overrun life – an expensive repair to the engine, such as the BMW S65 or Mercedes M156.

2. Endoscope Inspection

It is no longer an excuse that we cannot look inside because nowadays inexpensive digital endoscopes are very much available. Disconnect a spark plug and check the cylinder walls. The high-performance engines, such as the Ferrari F136 or GM LS7, have the cross-hatching that you are seeking. When the walls are mirror-smooth, the engine is losing compression and will either need a hone or a re-sleeve.

3. Harmonic Assessment

Listen for the “rhythm.” A V8 is supposed to be smooth and regular. Rhythmic tapping, which accelerates with the RPM, is usually a sign of wear in the valvetrain (lifters or rockers). This can be an indication of oil starvation to the top end of the Chrysler Hemi or Oldsmobile Rocket, a frequent problem when the car has not been started in a long time.

4. Parts Availability Check

The question to ask yourself before purchase is Who are the makers of the gaskets of this? The Small Block Chevy is an engine that is easy to get along with due to the availability of parts. A rare model of an ancient Cadillac V8? You will have to have a partner, such as Sunway Autoparts, who will be able to offer the sourcing or customization services of the best v8 model engine kit so that your investment does not turn out to be a 600-pound paper weight.

Conclusion

A mirror is normally the result of searching for the best V8 motor. In case you appreciate the history of the open road, the Ford Flathead is your hero. The Toyota 1UZ-FE is the only one that will allow you to experience the utmost luxury in the reliability aspect. And when you require the pure horsepower of the new era, the Coyote and LS series have never been defeated.

But the unifying factor about all ten of these legends is that they are all physical machines that are governed by the laws of physics and time. The best V8 engine to build is always the one that is in good condition, well-lubricated, and with high-quality replacement parts.

These V8s are a part of our culture, so to preserve them is a form of cultural conservation as we look into tomorrow. It may be rebuilding a Small Block Chevy or servicing a Ferrari F136, and you must remember that you are not just maintaining a machine, but a mechanical tradition. Make sure that legacy is not short-lived and select materials that do not eradicate the initial design, but also incorporate the standards of contemporary production.