To maintain optimal functioning, our cars have always relied on clean filters. The engine’s life is propelled by its motor oil. It preserves and improves the performance and productivity of the car’s engine. However, when the oil passes through the engine, it collects organic and inorganic pollutants that might damage the car’s engine, pushing it closer to its doom.

To avoid such problems, people consider purchasing oil filters that will cleanse the oil before it begins its journey through the engine. Read this post to learn about the different types of oil filters that may help the automobile or any other vehicle.

What is an oil filter?

An oil filter does exactly what it says on the tin: it filters the oil in the car’s engine. It’s a little component around the size of a tin of baked beans that’s critical to the engine’s flawless operation. The filter’s purpose is to clean the engine oil of any pollutants or polluting substances. If little flecks of hard objects get into the oil stream, they can rub up against critical machinery, causing them to wear out considerably quicker.

It is good to clean all of the engine oil to eliminate all of these pollutants before they cause serious harm to the engine’s functioning Bosparts. Because the engine’s functioning components will be damaged if the oil filter fails to remove pollutants, you’ll need to find the finest auto parts manufacturer to ensure you have parts that fit and run properly.

What are the Functions of Oil Filters?

Oil filters provide the following functions:

- As previously stated, engines produce dust, metal debris, oil carbons, and other combustion byproducts. This article in the oil is caught by oil filters before it enters the engine. The oil filter keeps the engine oil clean, which is important for constant engine performance.

- Soot contaminates and thickens the oil and dirt. Many thinning holes in oil filters prevent heavy oil from entering the engine via the pump.

- All moving parts, including connecting rods, camshaft, and valvetrain, are protected from wear and damage if the filter is working correctly.

Structure of oil filter

More than just contaminants are filtered by an oil filter. Its several parts work together to clean the oil and keep it in the right place at the right time.

Tapping Plate:

Oil enters and exits the oil filter through the tapping plate, which looks like a primary hole surrounded by smaller ones. Motor oil travels via the smaller holes, past the filter material, and then to the car’s engine through the center hole.

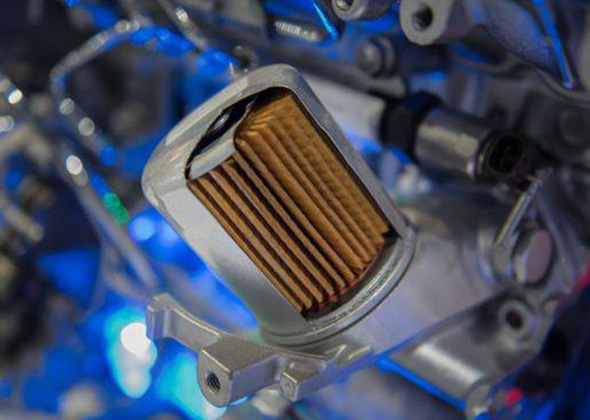

Filter Material:

A sieve made of synthetic fibers traps grit and debris in the engine oil. The material is pleated to enhance the surface area.

Anti-Drain Back Valve

When a vehicle is not in use, the Anti-Drain Back Valve closes to prevent oil from the engine from seeping back into the oil filter.

Relief Valve:

Engine oil can thicken and make it difficult to get through the filter when it becomes cold outside. The relief valve releases a little amount of unfiltered motor oil to give the engine a boost as it heats up.

End Discs:

Two metal or fiber end discs on either side of the oil filter keep unfiltered oil out of the engine.

How do oil filters work?

Early internal combustion engines lacked oil filters, and automobiles required regular oil changes due to the low quality of oil available at the time. A full-flow oil filtering system was eventually created. Essentially, this setup enabled oil to pass through the filter before reaching the engine’s main functioning components.

So far, so good, but there was (and still is) one key caveat: the great majority of pressurized lubrication systems utilized in internal combustion engines have a filter by-pass to protect the engine from starving under certain conditions. Extreme cold is a good example. If the oil is excessively thick, it is permitted to skip the filter in this circumstance. When the filter is clogged, oil might potentially bypass it. Oil is not always filtered as a result of these events, even when the engine is equipped with a full-flow oil filter.

Oil enters the oil filter through a series of tiny holes on the external edge of the base flange during operation. After passing through the filter, the oil is pumped into the engine through the huge center hole. Anti-drain back valves are standard equipment on most contemporary oil filters. The perimeter holes on the base flange are usually covered with a rubber membrane. As oil enters the filter housing, the membrane is yanked apart. The rubber membrane covers the apertures when the engine is switched off. Anti-drain-back valves, as the name implies, keep oil in the filter. As a result, the engine is unable to start dry (when the engine is started with no oil).

Types of oil filter media

Oil filters contain a variety of media (filter medium). The pollutants in the circulating motor oil will be filtered out and removed by this filter media. cellulose filter media, synthetic filter media, and micro-glass filter media are the most prevalent types of filter media. There are several different types of media and resin in industrial fluid filtering, including cellulose filter media, glass media, wire mesh, coalesce, and resin.

Cellulose Filter Media

Because it is very inexpensive to create, cellulose is a popular media type for industrial applications. It is the most prevalent organic polymer on the planet, derived mostly from wood pulp and cotton. Unfortunately, cellulose’s pore structure lacks homogeneity, resulting in poor fluid filtration and a low nominal rating.

With rising fluid temperatures, it is more vulnerable to structural manipulation, which can result in media migration or degradation of the media’s capacity to work its way into a system. Cellulose filters can collect particles, however, they are ineffective at retaining them. When dirt gets inside the filter, it gathers and then sheds, posing a serious threat to industrial systems.

Glass Media

Because of its consistent pore structure and longevity, glass media is given absolute ratings over cellulose. Most systems that use cellulose filters benefit immediately from glass media components. They can collect and hold around 49% more particles than cellulose and are less vulnerable to structural manipulation by increasing fluid temperatures.

Glass media is also impervious to particle shedding, ensuring that the dirt caught remains where it belongs: in the filter. Glass medium with a water removal additive package is also available. These water removal features provide enhanced particulate/water capture and retention capabilities, guaranteeing that not only the particles caught but also the water-absorbing gel, remain in the filter.

Wire Mesh

Wire mesh filters are commonly used in industrial filtration. Despite their poor reputation, they play a vital function. Unlike cellulose filters, wire mesh filters are far more durable, allowing them to collect and keep significantly more particles. As they were meant to be, wire mesh filters are suitable for power generation and other fire-resistant fluid applications, as well as long-term exposure to hostile fluids such as phosphate ester, Skydrol, deionized water, and high-temperature applications.

Coalesce

Coalescing elements work in a different way than water removal elements to remove water and provide dependable fluid filtration. Rather than gathering water in a gel, coalesce components separate free and emulsified water fluids and condense them to a weight that can be dropped and removed using a pleated synthetic structure.

Resin

Resin filters are one-of-a-kind not only in appearance but also in performance. Resin media is used to remove contaminant molecules that arise as a result of oxidation and fluid degradation from a variety of fluids at the molecular level. Polar oxides, acids, and other free radicals are the heavyweight molecules to be eliminated because they cause varnish development and degrade fluid performance.

Resin media is designed to remove contaminants selectively while leaving fluid additives alone. Resin results in fluids that perform better, endure longer, and provide trouble-free operation for those in charge of their maintenance.

Types of Car oil filters

There are multiple types of car oil filters that come in a variety of shapes and sizes, but they all serve the same purpose: to safeguard the engine’s health. The motor oil in an automobile absorbs pollutants that might harm the engine, and the oil filter filters it. It guarantees that the oil in the automobile is as clean as possible before it enters the engine.

Primary oil filter vs secondary oil filter

Primary oil filters

Primary oil filters are commonly available on most automobile engines. These full-flow oil filters filter all of the engine oil. These oil filters have reduced flow limitations since they must function properly to keep the engine lubricated. Motor oil thickens when the temperature drops and an oil filter that is too tight might cause engine harm. Smaller pollutants can thus slip past main oil filters. In the event that the filter membrane becomes too clogged, the manufacturer additionally installs a fail-safe bypass valve. If the filter clogs and motor oil cannot reach the engine, a special pressure system will guide the oil around the membrane to the engine.

Example: Bosch oil filter for Santro car. This car oil filter provides hassle-free use and is manufactured with great care.

Secondary oil filter

Some manufacturers use secondary oil filters in addition to primary oil filters. These oil filters remove a little percentage of the motor oil, usually 1% to 10%, before returning it to the engine. They aid by eliminating extra pollutants and act independently of the primary oil filters. As a consequence, the motor oil will have to be changed less often. Bypass filters are another name for these oil filters. It is crucial to note, however, that they are not the same as the bypass valve.

Example:

The above product is an aluminum and rubber product, with a 12-year warranty.

Full-flow oil filter

Many carmakers use this option, which is also known as a primary oil filter. While some filters clean only a fraction of the oil used by a car’s engine, a full-flow oil filter is designed to remove impurities from all of the oil used by the engine.

A full-flow oil filter is especially useful in the winter. The cold temperature will affect motor oil to thicken. If the filter is too tight, the engine may not get the oil it needs. A full-flow filter allows the motor oil to flow more freely through the engine when the temperature decreases, allowing it to provide all of the oil necessary for effective performance.

Some oil filters can only remove a few impurities from the oil, but this full-flow oil filter can remove all contaminants. This full-flow oil filter allows the oil to flow freely and without interruption. Other oil filters do not work in the same way.

Example:

Full Flow And By-Pass Lube Filtration

Filteration full flow

The most popular form of filter is the full flow filter, which collects all or almost all of the oil poured around the engine. They ensure optimal cold flow performance and filter life by providing vital engine protection. Full flow filters must be able to offer appropriate filtration, manage the needed flow rate even when the oil is cold, and contain enough debris. Conventional cellulose media filters will provide finer filtering and better flow with improved dirt holding capacity than synthetic media filters like Donaldson Syntec TM.

Filtration By-pass (secondary)

A by-pass filter, also known as a supplementary filter, is normally installed on a separate line and allows just a tiny portion of the total flow of oil to pass through before being routed back to the bottom. A bypass filter is generally a considerably finer filter than the entire flow to collect tiny particles. Because it is more efficient than a full-flow filter, it will have a significantly lower flow rate, especially when the oil is cold. It’s made to increase the oil’s overall cleanliness without harming the engine’s flow rate. Figure 2 on the right shows an illustration.

Filtration in two stages

The qualities of both a full flow and a by-pass filter are combined in a two-stage filter. The two-in-one design dramatically increases restriction, resulting in lower cold flow performance and shorter filter life. Poor cold flow performance depletes the engine’s oil supply during startup, leaving it vulnerable. Increased engine wear may result in early maintenance or possibly engine replacement as a result of this.

Cartridge Oil Filter

Another name for a cartridge oil filter is an eco oil filter. This type of full-flow filter is frequently recycled since it includes no metal fragments. It’s also simpler to utilize a cartridge oil filter. If the cartridge filter is positioned upright, a mechanic can usually inspect it without draining the engine oil.

This cartridge oil filter is likewise devoid of metal. Due to the lack of this metal, however, it is straightforward to utilize. If you’re looking for a simple oil filter that can be a hit in the market, this cartridge oil filter is a fantastic choice.

Example:

Spin-on oil filter

Aspin-on oil filter is a form of full-flow oil filter that is made up of a steel canister and a paper element. Car owners may easily fix it themselves because the installation is simple and requires little equipment.

Fram ph3560 oil filter for what vehicles

The Fram ph3560 oil filter is designed for fuel-injected engines with high-performance characteristics such as turbocharging and advanced ignition.

It is designed for use with common oil and has a larger media than the Fram Oil Filter Ph3675.

Example:

Spin-on oil filter vs cartridge oil filter

Manufacturers are beginning to abandon spin-on filters, owing to environmental concerns. California alone utilizes almost 67 million oil filters! Cartridge-style oil filters, which contain no metal and can be recycled or disposed of more easily than spinons, are one method OEMs and filter manufacturers are combating this rising issue. There is no perfect solution, however, because cartridge-style filters pose certain particular obstacles for both DIYers and professionals.

Despite the fact that cartridge-style oil filters precede spinons, OEMs are increasingly adopting plastic housings that must be removed with specific tools. Because the filter element is replaced every time the housing is resealed, wear and tear should be factored into the regular oil change with this type of filter. If the engineer isn’t cautious with the housing, the molded plastic may be harmed. It’s also more probable that the item will be installed incorrectly or with the wrong part size. The gasket must be replaced each time, and the screws should be coated to facilitate installation.

Spinner oil filter

A spinner oil filter is a sort of secondary filter that traps impurities in the car’s engine oil using centrifugal force. Some of these filters may create forces that are more than 2,000 times stronger than gravity. They may effectively remove even the smallest pollutants from the car’s engine oil.

This spinning oil filter has the ability to create two thousand times more force. The name spinner oil filter comes from the fact that these oil filters rotate. This oil filter will rotate in a circle, trapping pollutants in the engine oil. There are two chambers in this oil filter. We have the membrane and the housing chamber.

Some rotating oil filters may produce forces 2,000 times greater than gravity. This is why a bypass filter can remove even the smallest particles from the engine oil. A spinner filter generally has a filtering housing compartment and membrane (filter medium). A mechanic will only need to change the filter media if the filtration media becomes clogged; the filter housing chamber will remain functioning.

Another important component of a spinning filter is the base gasket. Its aim is to prevent the leakage of engine oil.

Example:

Magnetic oil filter

A magnetic filter, like a spinning oil filter, offers supplementary support to a full-flow filter. It successfully removes metallic impurities from the oil, but it leaves dust and filth behind. A magnetic oil filter, unlike other options, does not require replacement. All that is required to maintain this filter operational is regular cleaning.

However, the advantage of the whole magnetic oil filter is that it will not require any refills. This is advantageous since it allows you to save time and money by using this oil filter. Some oil filters must be updated over time as their quality deteriorates.

However, this magnetic oil filter will need to be replaced after a while. You just need to clean this oil filter on a regular basis to maintain its quality and function. The metallic particles in the motor oil may be removed with this magnetic oil filter.

Example:

Conclusion

Oil filters are critical components of a vehicle that must be maintained. To keep the engine protected from polluted oil, replace them or the filter element (if separable) as directed.

I hope that this blog has provided you with all of the information you want about oil filters, including the many types of oil filters and when to change a car’s oil filter. If you want an oil filter, contact automobile oil filter manufacturers, who provide oil filters for many automotive types. To ensure a proper fit, they are constructed using carefully selected raw materials and in accordance with OEM design criteria.