A vehicle is a combination of all types of parts that are constructed using all kinds of materials, each with a specific function. Some are made using metal; some are linked with wood, leather, and even plastic, all working with each other to ensure there’s proper balance.

We are going to explore the materials that are used in car parts manufacturing and look deeply at the requirements needed for the said parts to be made and the benefits they bring to the table for car owners. Knowing more about auto parts and manufacturing is helpful for you to identify the quality when sourcing auto parts.

Automotive Plastic Parts

Source: https://pixabay.com/photos/vintage-car-steering-wheel-turquoise-852239/

You will be surprised at the number of parts that are made using plastic parts in a car. They are one of the most versatile materials that help bring down the weight of the car. The common misconception is that since plastic is not as tough as metal, then plastic parts are weaker. That is not the truth on the ground; the flexibility that plastic parts offer is what makes them very strong as they are able to handle pressure.

Requirements of Plastic in the Auto Industry

Safety is at the core of car manufacturing because these are machines that have to be used on the roads by people. For this reason, there are some important requirements that the plastics being used have to meet, and they include the following.

- They have to be strong enough to withstand pressure and extreme conditions.

- They have to be flexible enough to be used to make various parts.

- They should be malleable.

Benefits of Plastic in the Automotive Industry

There are many benefits that the automotive industry derives from the use of plastic to make important components. Some of these benefits include the following.

- Plastic parts increase safety, and this has been proven through multiple tests. Unlike solid metallic parts that rarely bend, plastic parts are flexible enough to absorb most of the impact, and this increases safety.

- Plastic parts are lightweight, and this reduces the weight of the car, and consequently, the fuel needs of the car are also brought down significantly.

- Plastic parts are weather resistant. They can withstand any type of condition without losing their qualities. The only thing that can affect them is direct sunlight, and that only leads to mild discoloration.

- They have high compatibility with other materials, and this makes them the best when it comes to making accessories for vehicles.

Aluminum Car Parts

Source: https://pixabay.com/photos/mark-edelbrock-chromium-radiator-3416546/

Aluminum is a unique metal that has awesome, very interesting properties, one of them being that it is lightweight but extremely strong. Two properties are vital in making cars that are not that heavy but are strong enough to provide safety for the user. Some of the parts that make use of aluminum include hoods, bumpers, radiators, suspension parts, the engine, engine cylinder blocks, among many others.

Requirements of Aluminum in the Auto Industry

There are certain requirements that aluminum has to pass for it to be considered for use in the manufacturing of automotive parts. These requirements include the following.

- The aluminum material being used has to be strong enough to deal with the extreme conditions that cars go through, especially the movements.

- It has to be lightweight enough to not add unnecessary weight to the overall load of the car. When the car gets too heavy, the fuel needs increase too.

- It has to be flexible enough to absorb some impact when on the road as opposed to bending and breaking when a slight force is applied on them.

Benefits of Aluminum in the Automotive Industry

The use of aluminum in the manufacture of cars has a number of advantages that include the following.

- They are one of the lightest metals around. Their use greatly reduces the overall weight of the car, increasing fuel efficiency.

- They are resistant to corrosion. Once aluminum is exposed to the elements, it envelops itself in a coat that stops rusting once an oxidizing agent comes into contact with the metal.

- It is a very good conductor of heat and electricity, and both of these play a huge role in the functioning of the car. This is why every transmission line and electrical wiring is done using aluminum.

- It is a ductile metal with a good reflexive attribute that makes it ideal for use as rescue blankets and light fittings inside the car.

- Aluminum can be recycled and is one of the few metals that do so. The recycling can be done without aluminum losing any of its original properties, making it a very cost-effective automotive part material.

Steel Car Parts

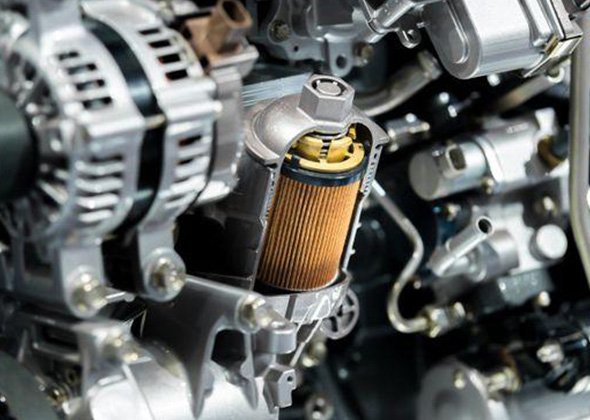

Source: https://pixabay.com/photos/car-engine-motor-engine-vehicle-1738366/

Steel is a very prominent metal that is heavily used in manufacturing around the world. It is among the most durable and heaviest metals on the planet, and the fact that it is highly abundant and versatile, it is not a surprise that it is heavily used in the making of some important car parts. Parts that are made using steel include car brakes, engines, wheels, exhaust systems, among many others.

Requirements of Steel in the Auto Industry

The following are some of the industry-standard requirements that steel has to have for it to be considered to be used for making car parts.

- It must be durable enough to last a user several years before they start thinking of finding replacements.

- It has to be compatible with other materials, especially other metals and plastics as well as carbon, which tends to make it stronger.

- It must be able to absorb some impact in order to protect the occupants of the car in case of an accident.

Benefits of Steel in the Automotive Industry

The following are some of the benefits of fitting cars with steel parts.

- Steel is one of the most durable metals around, and this comes in handy when making car parts as they ensure the user gets the most out of their car before they start planning for a new one.

- Steel can be reshaped and restored even after it takes damage. It may be strong, but it can be repaired quickly and even shaped into a better component.

- You don’t need to make too many jins when making car parts from steel. This increases the strength since more joints make more weaknesses.

Rubber Automotive Parts

Source: https://pixabay.com/photos/tyre-wheel-tire-car-automobile-1714669/

Rubber is used virtually in any industry you can think of. It has some exciting properties like the flexibility that make it the ideal material for creating most of the interior and exterior parts of a car for extra comfort. One of the most visible car parts that make use of rubber is the tires, and this is due to a number of attributes that make them the safest material for that particular role. Other parts that are made using rubber include floor mats, seats, airbags, mud flaps, among many others.

Requirements of Rubber in the Auto Industry

When you consider the vital car parts that can only be made using rubber and nothing else, the requirements for rubber are a bit more stringent, and they include the following.

- Rubber must have good traction that increases friction for it to be used to make wheels. This is important as the safety of the car greatly depends on that one feature.

- Rubber has to be malleable enough to be adopted for a number of other uses inside and outside the car.

- Rubber must-have attributes that make it not only durable but grants it the ability to deal with the elements without putting the car at risk.

Benefits of Rubber in the Automotive Industry

Rubber has a number of benefits when used in the manufacture of car parts, and some of the most notable ones include the following.

- Rubber has great abrasion resistance, thanks to its flexibility. When the rubber meets an immovable force, it simply gives way and absorbs that impact.

- It can withstand both hot and cold conditions, and this is part of the reason why there’s no alternative to rubber when making car tires, for instance.

- It has great chemical resistance, and this is good for durability.

Glass Auto Parts

Source: https://pixabay.com/photos/oldtimer-car-interior-steering-605509/

Glass is used for a number of functions in car manufacturing. They may be the most fragile material on this list but they do serve an important function. Notable is their role as windshields, car windows, and housing for car lights. Although clear plastic is another alternative, glass is much preferred as it is heavier, easier to deal with, and doesn’t scratch easily.

Requirements of Glass in the Auto Industry

There are certain requirements that glass must meet for it to be certified safe for use as a car part. These requirements include the following.

- Glass must have the ability to shatter into smaller pieces in the event of a crash. This is for the safety of the car occupants since smaller glass pieces pose less danger to the people.

- It must be clear and transparent for the best visibility possible. It should be able to be used even in bad weather without any issue.

- The glass should be tempered and must have undergone proper heat treatment to make it durable and strong enough to deal with elements outdoors.

Benefits of Glass in the Automotive Industry

There are many benefits of using glass in making certain parts of the car despite their fragility. Some of the most notable ones include the following.

- They provide protection for the occupants of the car from the elements when working alongside the body of the car.

- Their transparency provides the view needed for the car to be operated. They act as the shield against the wind and flying objects.

- They give structure to the car. You can’t think about what a car looks like without a picture of the shape and design of the window and windshield glass.

Fiberglass Car Parts

Source: https://pixabay.com/photos/car-audi-headlight-red-light-368636/

Fiberglass is simply plastic that has been reinforced with glass fibers mixed up with a resin material. This makes it stronger and more durable than common glass as it is harder to crack or break. Some of the parts that make use of fiberglass in car parts include entire bodies, headlight covers, among many other bigger and smaller car parts.

Requirements of Fiberglass in the Auto Industry

Being stronger and more durable than regular glass, the requirements for the user of fiberglass are not that strict, but they still have to be followed. They include the following.

- Depending on where they are used, they have to be strong enough to protect the car from the elements and other objects when the car is in motion.

- Fiberglass has to be lightweight enough to reduce the overall weight of the car but, at the same time, reliable enough to stop physical damage significantly.

- Due to the addition of resins, the fiberglass has to be shatterproof. This is why fiberglass is replacing regular glass for most car parts.

Benefits of Fiberglass in the Automotive Industry

Fiberglass has revolutionized car manufacturing in a very huge way, and the following are some of the benefits of using it for making some specific car parts.

- Fiberglass is stronger and resistant to cracks. You will have to apply a lot of pressure for fiberglass to sustain any serious damage.

- Fiberglass is corrosion resistant, and the parts made using them tend to last longer and look better.

- They have a superior weight-to-strength ratio that is way higher than that of glass or other materials that may be used in making the body of the car.

- Fiberglass is cost-effective as it is cheaper to make and use.

- It is a non-conductor and has the ability to be molded into different shapes depending on the manufacturing needs.

- Fiberglass gives the car a very nicer appearance and can be combined with different shades to create exciting colors that are common for people who love customiz\ed vehicles.

Carbon Fibre Car Parts

Source: https://pixabay.com/photos/cadillac-car-auto-american-usa-4645501/

Carbon fiber is one of the hardest and toughest materials used in making car parts and also one of the most expensive; this is why they are mostly found in high-end cars. Carbon fiber makes use of special carbon to make materials that are hard to break. Some of the car parts that are made using carbon fiber include bumpers, spoilers, wheels, among many other parts.

Requirements of Carbon Fiber in the Auto Industry

Just like any other material used in making auto parts, carbon fiber still has some requirements that it has to pass before being used for the same. These requirements include the following.

- The ability to provide protection for the car and absorb any impact to protect the occupants from significant harm.

- The ability to be used alongside other materials without compromising the functionalities and efficiency of the vehicle.

- The ability to be shaped into any desired design that further enhances the needs of the car.

Benefits of Carbon Fiber in the Automotive Industry

Carbon fiber is one of the most sought-after materials in all levels of manufacturing and having it as part of car components significantly raises the profile of the same car. The following are some of the benefits you get from using carbon fiber parts.

- Carbon fiber is very lightweight but super solid. This goes the car parts durability while reducing the overall weight of the car. This is effective in reducing fuel needs.

- Carbon fiber has a high resistance to corrosion. It can withstand all kinds of weather and chemicals that are thrown at it. This is one of the reasons why it is very costly.

- Carbon fiber has high flexibility that allows for intricate patterns and shapes to be woven, giving the car a very aesthetic appeal.

- Carbon fiber is a thermal-friendly material that is best known for accommodating all kinds of expansion. This gives it the ability to cope with the stress that comes with the expansion and contraction of car parts in varying conditions.

Magnesium Car Parts

Source: https://pixabay.com/photos/car-steering-wheel-classic-car-1544342/

Magnesium is another metal that many car manufacturers are slowly starting to adopt as it is lightweight and resistant to most chemicals. It is also highly resistant to the elements and this increases the safety of the car when some of the parts are constructed with it. Some of the common parts that are made using magnesium include the gearbox, airbag housing, steering columns, front-end IP beams, among many others.

Requirements of Magnesium in the Auto Industry

The use of magnesium is not as widespread as most of the other metals, but the few that make use of it follow some requirements before making any part. These requirements include the following.

- The magnesium has to show its ability to resist some common chemicals that it may come into contact with when used as a car component.

- The magnesium has to be solid enough to be used for very long without showing any signs of wear and tear. It is costly having to replace parts every year.

- It must be flexible enough to be beaten into any shape but strong enough to withstand impacts.

Benefits of Magnesium in the Automotive Industry

There are several benefits that are associated with using magnesium in the automotive industry. These include the following.

- Magnesium is cheaper than most of the other materials on this list, and this makes it a cost-effective material for making small parts that require mass production at once.

- Magnesium has a very good chemical and heat resistance, and this makes it ideal for constructing safety parts of their vehicle.

- Magnesium is not as heavy as most of the other metallic counterparts. This reduces the overall weight of the car, which in turn reduces the fueling needs of the car.

- Magnesium doesn’t tarnish easily, even when exposed to the elements for very long. A car that has parts made of magnesium always sports a very cool look.

Titanium Auto Parts

Source: https://pixabay.com/photos/car-benz-mercedes-rim-tyre-black-4048220/

Titanium is one of the hardest metals around, with a very high tensile strength of about 63,000 PSI. This is what you go for when you want to make car parts that will last you a lifetime. But that comes at a very high price. Some of the car parts that are made using titanium include engine valves, turbocharger parts, connection rods, exhaust systems, among others.

Requirements of Titanium in the Auto Industry

As far as the basic requirements for making car parts go, titanium basically ticks all the boxes. It has the tensile strength to counter impacts, the flexibility to be shaped into anything, and it isn’t as heavy as steel. The only thing you have to be on the lookout for is the price tag. It is not cheap.

Benefits of Titanium in the Automotive Industry

There are several advantages that come with using titanium to make car parts that are used both inside and outside. The benefits include the following.

- Titanium has a low density, and this makes it lightweight enough to be used in any part of the car without having to raise the overall weight significantly.

- It improves efficiency by reducing fuel consumption, and at the same time, it is not toxic to the environment.

- Titanium makes durable parts that can be used for years to come without ever having to worry about making repairs.

- Titanium has a very aesthetic appearance that will improve the general outlook of the car. This is why you are most likely to find titanium parts in high-end luxury cars only. Accessing the metal is not that easy for most carmakers, which is why it is costly.

New Materials in the Automotive Industry

Source: https://pixabay.com/photos/auto-automobile-automotive-amg-2179220/

There are a number of new materials that are coming up to replace most of those that have been mentioned above. The reason why manufacturers are looking for alternatives is due to the glaring fact that dwindling resources are making some of the metals that used to be abundant hard to find. The following are some of the new materials being used as alternatives for making car parts.

- Metal Alloys: Metal alloys have been used for aghes to improve machines and the same is being improved further in the automotive industry. Car makers are now experimenting with new alloys like aluminum and carbon to further improve the quality of car parts and push their lifespan higher.

- PLA and Flax Seed Fibers: Carmakers are now leaning towards sustainability by combining natural organic fibers to make solid materials that can be used to make reliable car parts. PLA and flax seed fibers are just some of the few that have shown promise so far.

Conclusion

Car-making technologies and processes continue to improve over the years, and evidence points towards a future where cars will be using new materials that we are yet to discover for their main parts. To learn more about automotive parts and how they are made and applied, check out our website.