Introduction: How Profitable is the Classic Car Restoration Business?

The biggest question that would be posed by the aspiring shop owners could be: Is there even money in this? The brief reply is yes, but margins tend to be lower than what outsiders think.

The average general automotive repair shop would strive to achieve a net profit margin of 20-25%. A net margin of 10-15% is healthy in the classic car restoration business, and the best shops have a net margin of 20% through strict efficiency. The reduced margin can be attributed to the unknowns, to concealed rust, unfit parts, and to sheer labor intensity of the job.

There are two sources of profitability:

- Labor: The skilled work is to be paid per hour.

- Parts and Materials: Markup on the used components in the build.

The result of underestimating the bay blocking effect causes the failure of many businesses. When a car is in a bay waiting to be parted or one awaiting a decision on the part of a client, it is not making any money; it is costing you rent. As such, the profitability of your business is directly proportional to how well you are able to keep the projects running.

Market Research: Choosing Your Specific Niche

Attempting to revive it all is one of the biggest errors made by new entrants. The shop that takes in an old 1930s Ford Model A one week and a 1980s Ferrari Testarossa the next will find it difficult to develop the specialty tooling, network of parts, and knowledge base to be efficient.

The key to success is in specialization. When you specialize in a particular time, brand, or design, you are the expert.

Concours-Level Restoration vs. Driver Quality

The key decision-making is to determine the level of restoration to be sold because it should not be based on the same business model.

The quest for perfection is the Concours-Level Restoration. It is aimed at restoring the car to the same clean state it came out of the factory (better), and even to the proper hose clamps and overspray marks.

- Pros: Expensive prices (six figures); a prestigious reputation.

- Cons: Incredibly high demands; the projects may take 2-3 years; searching the parts of New Old Stock (NOS) is a nightmare.

Driver Quality emphasizes mechanical reliability and good cosmetics, but not perfection. These are not cars to be parked on the lawn at Pebble Beach and driven on weekends.

- Pros: More prompt delivery; increased customer base; easier access to parts.

- Cons: Reduction of profit per unit of car; has to sell more cars to recover the same income.

The Rise of Restomods and Modern Upgrades

The Restomod market is the most profitable market in the classic car restoration market currently. It includes the process of acquiring a traditional chassis and equipping it with a new suspension, fuel-injected engines, air conditioning, and safety systems.

It is indicated that Gen X and Millennial consumers are willing to buy Restomods due to their desire to have the appearance of an old car, but with the safety features of a daily driver. This niche is desirable to a business owner since it tends to make use of new aftermarket components instead of searching through rare, used parts, and thus makes the supply chain more predictable.

Developing a Robust Business Model and Financial Plan

The Fixed Price Quote is the financial suicide trap of this business.

Do not give a fixed charge for complete restoration. The rust that is in a frame rail cannot be seen until the car is sandblasted. Suppose you offer to pay me $50,000, and the metalwork by itself costs me $40,000, you will go out of business trying to pay me the money.

Rather, the sustainable business custom of the industry is the so-called Time and Materials model:

- Labor: Billed every two weeks in accordance with the real hours worked.

- Materials: According to the purchased billing, with a usual standard markup (usually 20-30%).

Management of Cash flow is also important. The restoration of a building is a marathon, not a sprint. You should also organize your payments in a way that you are not ever financing the project of customer out of pocket. A common structure is:

- Deposit: To book the slot in the schedule.

- Draw System: The customer has a renewable deposit (e.g. $5,000). As you work, you draw from this. As soon as it reaches $1,000, it is stopped until it has been replenished.

Navigating Legal Obligations and Specialized Insurance

You are in charge of high-value assets, which otherwise are impossible to replace. A normal business liability insurance policy is inadequate.

You particularly require Garage Keepers Legal Liability insurance. This applies to the vehicles when they are in your care, custody, and control. In case your shop catches fire or a technician crashes the Jaguar E-Type belonging to a client during a test drive, you will not be bankrupt anymore thanks to this policy.

More so, your contracts should be iron-clad. They need to include:

- Mechanic’s Lien rights: This is the legal right to keep the vehicle when the bill is not paid.

- Testing permission: License to drive the vehicle on the roads.

- Disclaimer for “hidden damage”: It should expressly declare that initial estimates are not binding caps.

Essential Workshop Requirements and Equipment

The workshop layout brings forth efficiency. Another rule of thumb is that one active restoration bay should have one storage bay part and the disassembled shell. A 2,000 sq. ft. shop may be big, but when you blow 3 cars to pieces, it gets smaller in a minute.

The necessary and advanced equipment is divided as follows:

| Category | Essential Starter Equipment | Professional Grade / Advanced |

| Lifting | 2-Post Hydraulic Lifts | 4-Post Storage Lifts, Rotisseries |

| Metalwork | MIG Welder, Angle Grinders | TIG Welder, English Wheel, Planishing Hammer |

| Surface Prep | Sandblasting Cabinet | Media Blasting Room, Vapor Honing |

| Finishing | Outsourced Painting | Down-draft Paint Booth with Baking Cycle |

| Organization | Heavy Duty Racking, Parts Bins | Digital Inventory Scanning System |

Building a Skilled Team in a Labor-Short Market

Automation of the automotive workforce is a big challenge: the process of graying. The professional craftsmen are retiring in large numbers, and the young are not joining the trade in large numbers. You cannot just find the typical mechanic to build a team.

You are not seeking parts replacers; you are seeking problem solvers.

What skills and knowledge are essential for successfully restoring classic cars?

Your staff requires an integrated set of skills that cover almost twenty years of automotive technology to operate a full-service shop:

- Fabrication and Metallurgy: Capability to make sheet metal out of nothing, as replacement sheets are unavailable. Knowledge of the effect of aging and welding of various metals (steel vs. aluminum).

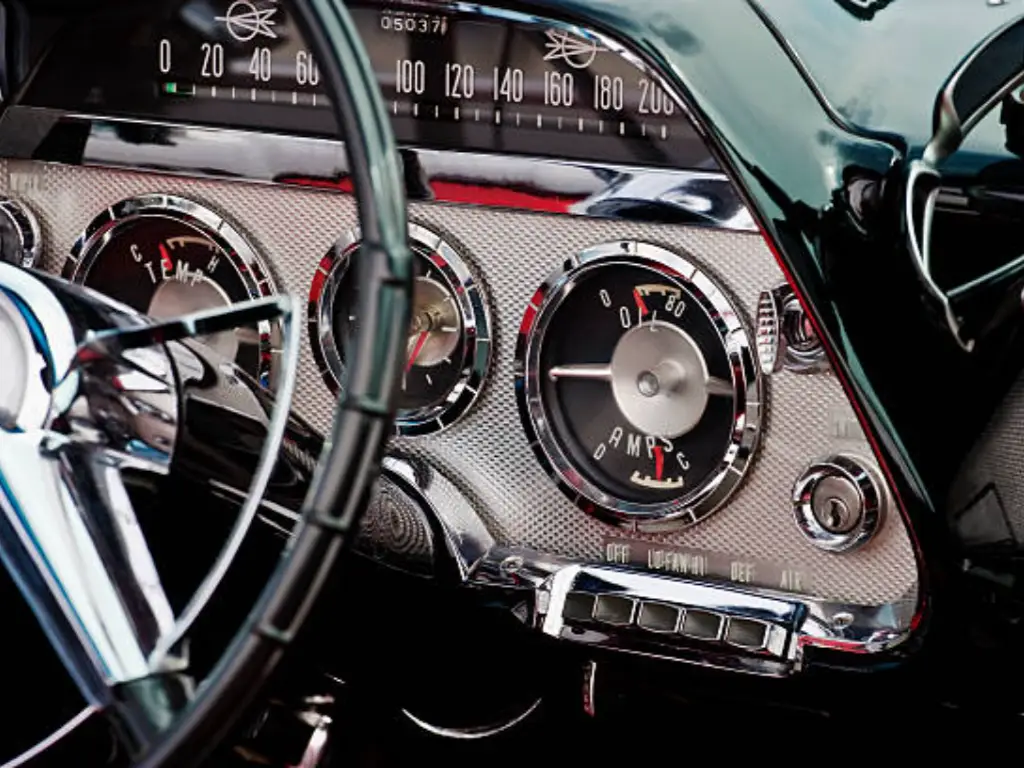

- Old-School Diagnostics: Understanding of carburetors, points distributors, and mechanical fuel pumps – systems that are not readable by modern OBD-II scanners.

- Creative Problem Solving: It is often the case that the manual does not exist. A technician should be in a position to reverse engineer a solution or modify a contemporary part to an older application, and not destroy the look.

- Patience and Detail Orientation: When compared to collision repair, which is concerned with speed, restoration is concerned with precision. The person who seems to hurry is going to make you spend money on rework.

The Supply Chain Challenge: Sourcing Quality Parts Efficiently

The mundane aspect of a traditional car restoration company is supply chain management. The 12-month project can easily get to 24 months just because you are waiting to get chromed trim or a certain suspension bushing.

This lag is not only exasperating, but it also kills profitability. When a car is lying around waiting to get parts, it is taking up some square footage that could be making money. Moreover, low-quality components cause enormous increases in labor expenses. When one of the technicians is spending 4 hours adjusting a new fender to fit, then your profit margin on that job disappears.

Why Direct-to-Manufacturer Sourcing Boosts Margins

Conventionally, shops purchase from retailers or eBay. Although good when it comes to single purchases, this cuts into profit lines and creates doubt about quality.

In the case of business, it is a good strategy to develop a Direct-to-Manufacturer relationship.

- Cost Control: The closer you are to the source, the higher your markup potential is.

- Consistency: Retailers are known to alternate suppliers on the basis of the lowest bid. Manufacturer partnership means that you will receive the same quality each time.

- Availability: Direct partners can possess more stock levels than consumer-facing retail websites.

Partnering with Specialists: The Sunway Autoparts Advantage

It is at this point that the selection of the appropriate partner is no longer seen as a procurement thing, but rather as a competitive advantage. In the case of companies whose models fall between the mid-1920s and the late 1990s, including Ford, Volkswagen, Jaguar, and Chevrolet, sourcing of parts that can fit the first time is the most important thing.

Since 2007, Sunway Autoparts has built a niche as a vendor, but also as a supply chain partner in the restoration business.

- Resolving the Fitment Crisis: The largest complaint in the industry is that the reproduction parts do not fit compared to the original parts. It specializes in the reproduction of OEM-level parts, and with the help of modern injection molding and tooling, Sunway is able to make parts in accordance with the specifications.

- Material Improvements: The materials are not the same, but the specs are. Sunway also makes use of the newest, UV-resistant plastics and high-quality rubber compounds so that the components you install in a year or two will not crack or fade in two years like the New Old Stock (NOS) parts that have been on a shelf since the 1960s.

- One-Stop Supply Chain: The number of suppliers that a shop owner has to deal with is 200, which means a nightmare in terms of logistics. Sunway has a concentrated network of almost 200 suppliers and hundreds of products. They provide a B2B solution that is straightforward and forward, whether you require an individual component to be fabricated or a standard production part to support a batch of Mustangs.

In the case of a restoration shop, a partner such as Sunway would imply standardized inventory and customizable batch ordering, and you are able to concentrate on the craft rather than pursuing tracking figures.

Client Management: Transparency, Contracts, and Communication

Failure to communicate is the foremost reason why clients take cases to court over the restoration shops. Such a client will think the worst when he or she deposits a sum of 50,000 and does not see you in three months.

Install a stringent Transparency Protocol:

- Weekly Digital Updates: Have a common Google Drive or Dropbox folder. Post pictures of the progress made each Friday. Although the progress is simply the one saying that the left door was sanded, the client must see it.

- Change Orders: In case the client decides halfway through the decision that they want to have a leather interior rather than a vinyl one, record it. Have the price difference signed, and then place an order for the leather.

- Educational Strategy: The majority of clients are unaware of the work that goes into it. It is your job to educate them. Give the reason why block sanding will take 40 hours. They will have fewer chances of challenging the bill when they know the process.

Future-Proofing: Staying Ahead of Industry Trends

The world of classic cars does not stand ground. Although metalwork and painting retain their basic skills, the technology surrounding them is changing.

EV Conversions are not a niche anymore; it is a segment that is expanding fast. Due to increasingly stringent emissions regulations in urban areas, one of the skills you may need to future-proof your business is to know how to fit electric powertrains to old chassis. Equally, 3D Printing is necessary to reprint unavailable trim pieces or plastic clips that have not been printed in 50 years.

Marketing Your Brand and Building a Portfolio

The era of the digital age has your workshop as a content studio. The visual aspect of a classic car restoration company is the marketing gold.

- Document Everything: Your resume is in the form of high-quality before and after photos.

- YouTube and Social Media: You do not have to be a film-maker, but easy time-lapse videos of any engine rebuild or paint correction prove that you are skilled and open.

- The Narrative: Sell the story, and not only the repair. Post a photo, describe the history of the car. The people are giving you their memories and their dreams: show them that you value that tradition.

Conclusion

The key to opening a business that successfully restores classic cars is a juggling act of balancing between the past and a modern business. It involves a strong appreciation of the history of auto, maintaining an objective and careful attitude towards money, and the vision of creating a supply chain that augments your operations instead of creating a drag upon them.

You can establish a business that is as long-lasting as the cars you are restoring by selecting a niche, making sure your business is legally safe and reliable with companies like Sunway Autoparts to manufacture quality and efficient parts. The market is anticipating the professionals who could deliver the quality in transparency, then get your engine on.