Few things in driving are as irritating and even dangerous as putting your steering wheel into a very important position and getting no response. The car horn is an essential element of defensive driving, whether you are trying to warn an errant driver who is joining your lane or you are merely waving to your friend.

Most drivers cannot think of anything worse than a faulty horn: they are heading to the motor shop and paying a lot of money to have it fixed, or they are entering a complicated technical issue. But the truth turns out to be far more basic. According to industry statistics, almost 80% of car’s horn failures can be attributed to small electrical impairments (such as a blown fuse or stuck relay) that can be repaired in a driveway at a cost of less than a lunch.

This is a guide to a professional-quality diagnostic process, starting with the easiest tests and then progressing to more challenging electrical tests. Additionally, to the car history enthusiasts, we have devoted a dedicated section to the relic issues of classic and vintage vehicle horn systems.

Why Did My Car Horn Stop Working Suddenly?

The mechanism of the car horn is quite simple in its electrical circuit: a battery is connected to a fuse, which leads to a relay, and then to the horn unit, which is activated by the steering-wheel switch. This system is vulnerable to vibration, temperature, and moisture (this is particularly true when horns are mounted behind the front grille). It is vulnerable to failure; it is just a matter of when, rather than whether.

The most typical offenders are:

- Blown Fuse: When the current is large, the fuse may melt the fuse filament to save the other parts of the circuit.

- Bad Relay: The relay that controls the high current of the horn has a tendency to break after years of clicking.

- Corrosion: The connectors or the internal mechanism of the horn may be rusted by ingested water.

- Clock Spring Failure: This is the spiral cable in the steering wheel that ensures contact when you turn. It can break.

Step 1: The “Click” Test (Listen Before You Touch)

Your best diagnostic tool before you open a toolbox or pop the hood is your ears. This step is aimed at isolating the point at which the circuit is not connected: is it the signal leaving the steering wheel, or is it getting lost on its way to the horn?

Park the car in a still area, switch on the ignition to the On or Accessory (engine off) position, and crack the hood. Make a helper keep pressing the horn button, as you listen closely to the fuse box and the front grille.

If You Hear a Clicking Sound

Actually, it is good news when you hear a very loud click in the fuse box area each time you press the horn.

- What it is: Your steering wheel switch, the so-called clock spring, and low-current wiring between the wheel and the relay are all in order. The relay is engaging.

- The probable victim: What is downstream of the relay is the problem. Probably it is a dead horn unit or a corroded wire that joins the relay to the horn.

If There Is No Sound at All

When you press the horn and hear not a single click or hum, you are breaking an upstream circuit. It means the relay is not receiving power.

This normally refers to an exploded fuse (the most common cause), a faulty relay, which is completely stuck open, or a broken switch/clock spring in the steering wheel.

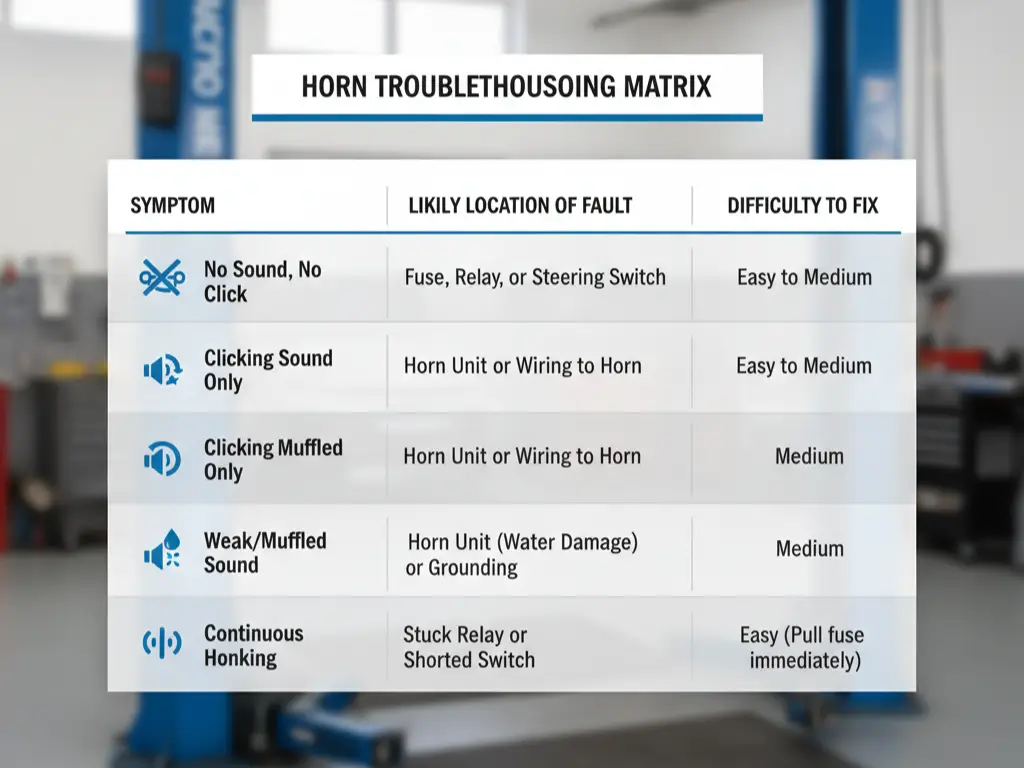

In order to aid in visualizing the diagnosis, use the following quick troubleshooting matrix:

Step 2: Check the Horn Fuse

In case you have an empty test in the “Click Test,” the first physical examination should be the fuse. This serves as the electrical system safety gatekeeper.

- Find the Fuse Box: Find the owner’s manual. The majority of the horn fuses are installed in the engine bay fuse box (Power Distribution Center), although in some cars they are installed in the cabin panel close to the driver’s knee.

- Determine the Fuse: On the lower part of the fuse box lid, seek a diagram. Find the slot labeled “HORN.”

- Inspect: Use a fuse puller or a needle-nose pair of pliers to pull the fuse out. Hold it up to the light. The fuse is blown in case the U-shaped metal filament in the plastic housing is broken or has a dark, burnt spot.

- Replace: Replace it with a fuse of the exact same amperage (typically 10A, 15A, or 20A).

Note: When the new fuse blows as soon as you press the horn, you have a short circuit in the wiring, which needs to be fixed by a professional.

Step 3: Inspect and Swap the Horn Relay

When the fuse is good, and the horn still will not sound(and you hear no clicking), the next suspect is the relay. Relays are simply switches that are controlled remotely, and they have to deal with the high electrical current needed to produce a bang out of a working car horn.

The Swap Method is the surest method of testing a relay without any sort of special equipment.

- Find a Match: Check the rest of the relays in the fuse box. Manufacturers normally apply the same relays on various systems (e.g., the A/C compressor, defogger, or fog lights).

- Check Part Numbers: The part number, which is printed on the top of thehorn relay, must be identical to the part number on the top of the “donor” relay.

- The Swap: Insert the known working relay (e.g., of the A/C) into the horn slot.

- Test: Press the horn. And in case it is working at this time, then your old relay was faulty. The replacement relay is a budget-friendly purchase, ranging between $10-$20 in any auto part store.

Step 4: Testing the Horn Unit and Ground Connection

In case your fuse and relay operate (or you heard clicking in Step 1), it is a problem with the horn itself or the final wiring. The car horns are hard to clean; they are low-mounted on the front of the car and get wet during the rain, road salt, and garbage.

Using a Jumper Wire for Direct Power

The horn should be tested independently to eliminate the possibility of a broken wire in the car harness.

- Find the horn (mostly behind the grille or close to the radiator support).

- Detach the wire connector that is on the horn.

- Connect a jumper wire (extra spare wire with alligator clips) to the positive terminal of your car battery to your horn in the positive terminal.

- Findings: A loud sound when sounding the horn means that the horn is okay, and the check must be that the wiring harness of the car is not broken. In case the horn does not reply or produces a faint “thud,” the mechanism internally is captured or fried off, and the unit is required to be replaced.

Cleaning the Ground Point (Crucial for Older Vehicles)

There must be a return connection to the battery, the so-called ground. In 90% of cars, the horn grounds itself in its metal mounting bracket, which is a bolt connected to the chassis of the car.

With time, rust and oxidation develop between the horn bracket and the car frame and eliminate the circuit. This is mostly prevalent in motor vehicles aged more than 10 years.

The Fix: Unbolt the horn. Clean the metal of the frame and the horn bracket with a wire brush or sandpaper until you observe glossy bare metal. Reattach the bolt tightly. Frequently this mere cleaning is sufficient to rebuke a dead horn to its proper volume.

Step 5: Advanced Issues: Wiring and Clock Spring

When you observed that the fuse, relay, horn unit, and ground have been checked and the system still does not work, then the Clock Spring is probably the culprit.

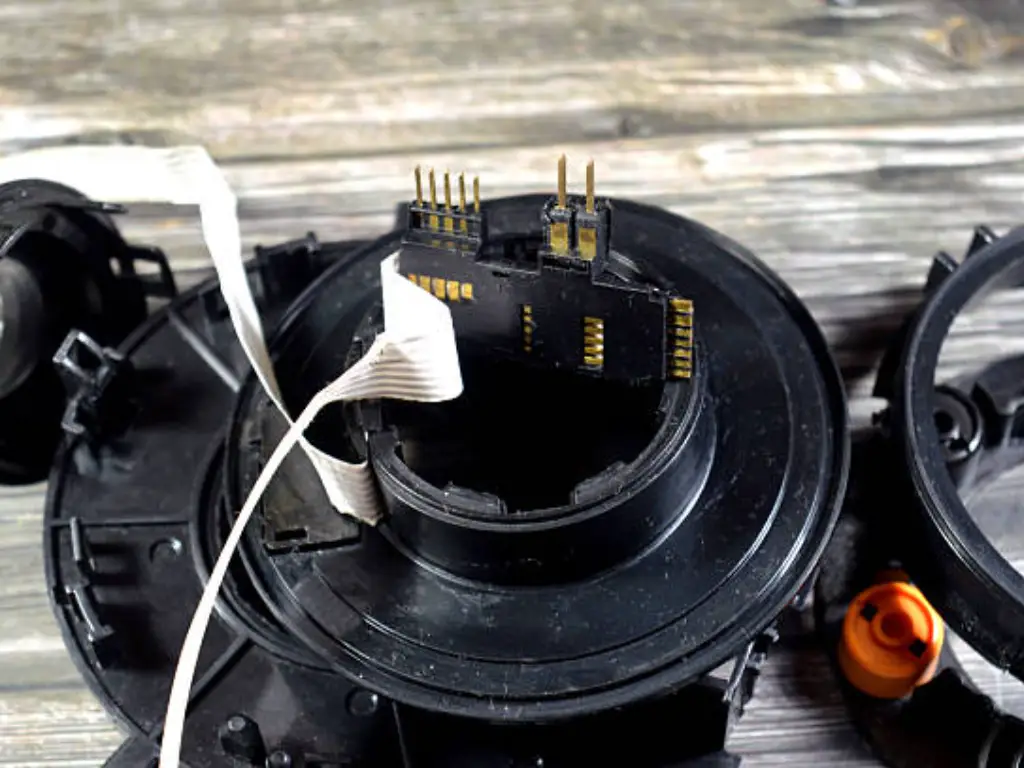

The clock spring is a ribbon cable that is wound around the steering wheel, and it is through this that electrical connections (airbag, horn, cruise control) can still be made when you turn the steering wheel.

Caution: A broken clock spring will frequently cause the Airbag (SRS) Warning Light to appear on your dashboard.

- Diagnosis: When your horn no longer functions and your airbag light is on, then there is a very high probability that your clock spring is torn.

- Action: You should not undertake to fix this yourself unless you are specifically trained to do so. Defective management of the clock spring may lead to the unintentional release of the airbag that will cause serious injuries. It is the step at which professional repair is highly suggested.

Special Section: Troubleshooting Classic & Vintage Car Horns

The fundamental physics of electricity are unchanged, but the conditions of a horn on a 1965 Ford Mustang or a 1950s Volkswagen Beetle do not pose the same set of issues as a Honda would.

Vehicles made in classics work in a world of mechanical connections and worn-out metallurgy. You simply cannot take a “modern parts swapper mentality to diagnostics, should you be a restoration enthusiast or the owner of a classic car. You have to be aware of the particular weaknesses of old buildings.

Why Vintage Horn Systems Fail Differently

In vehicles of today, failure is mostly electronic. The failure in classic cars is usually environmental and mechanical.

- Chassis Grounding Problems: Vintage cars are highly dependent on the use of the chassis in providing grounding. Fifty years old car, there might be several layers of paint, rust, or undercoating that break the groundline every decade.

- 6-volt vs. 12-volt Systems: A number of pre-1955 vehicles can run on 6-volt systems. A 6-volt horn is very sensitive to resistance. Even minimal corrosion that would be overcome by a modern 12-volt system can render a 6-volt horn silent.

- Diaphragm Stiffening: Older horns are powered by the use of a metal diaphragm. This metal may fatigue or rust after 40+ years, and the internal contact points (breaker points) may oxidize, and this has to be adjusted by hand or filed, something that is impossible to do on closed modern plastic horns.

Restoration vs. Replacement: What is Best for Your Classic Car?

Owners of classic cars are in a dilemma when it is confirmed that the car horn is dead. Would you do a search of the salvageyards in search of a so-called New Old Stock (NOS) component that could cost you hundreds of dollars and break in a month? Or do you lock on a plastic horn of a generic variety that belongs to a local automobile store?

The dangers of using generic replacements of moderns.

Fitting a replica modern horn on a vintage car is usually wrong.

- Aesthetic Clash: A shiny plastic orb that can be seen through the chrome grill of an old Jaguar or Chevy does not visually fit in.

- Wrong Tone: Horns, nowadays, are sounding odd and high. Their tone is not very deep, melodic, or commanding as it would be period-correct in vehicles of the middle of the 20 th century.

- Durability Problems: Generic aftermarket components are not necessarily made to last, but their prices are intended to be the lowest.

Sunway Autoparts: Authentic Sound with Modern Reliability

To the vintage enthusiast who must have both the authenticity and functionality, Sunway Autoparts makes the connection between the old and the new.

Sunway has been in the niche market of classic auto parts since 2007, specializing in models as old as mid 1920s and the latest as late 1990s. It does not matter if you are restoring a Ford Model A, an old VW Beetle, or a classic Chevy; the objective is to preserve the soul of the vehicle but not to inherit its mechanical issues.

Sunway Autoparts has a unique feature in terms of restoration work:

- OEM Standards, Contemporary Materials: We study the original requirements of the traditional horns but produce them with better technology in modern plastic injection molding and tooling. This makes the part look and sound like it was built in 1960 and provides the strength of 2025 technology.

- Supply Chain Depth: We have almost 200 suppliers in our network, and control hundreds of product families, which is why we solve the problem of the headache of hard-to-find parts.

- Customization: We know that each build is different. Our customization service is available on special requests, so that your horn is not an ordinary part, but a unique element of your car.

| Feature | Generic Aftermarket Horn | Sunway Autoparts Classic Horn |

| Visual Appearance | Modern Plastic / Universal Fit | Period-Correct / OEM Style |

| Sound Profile | High-pitched / Generic Beep | Vintage Tone / Deep Resonance |

| Durability | Low (Consumer Grade) | High (Industrial Tooling Standards) |

| Compatibility | Requires wiring modification | Designed for Classic Voltages/Mounts |

When you have a restoration shop or a wholesaler, Sunway is also a consistent upstream partner that can offer a steady supply of quality and flexible batch options to keep your inventory moving.

Conclusion

It does not matter if you have a commuter or a showroom quality classic, as long as a horn to honk works or not, as far as safety is concerned. In the case of modern vehicles, it might be as straightforward as a replacement of a fuse costing $5 or a simple cleaning of a ground wire.

Nevertheless, in the case of classic vehicles, the horn belongs to the car’s voice. Keep quiet, horns off your neck, or the nature of your car. Should your old horn have sung its swan song, it is time to think about something that pays tribute to the history of your machine, and be sure that you have enough power to be heard by everyone on the highway today.